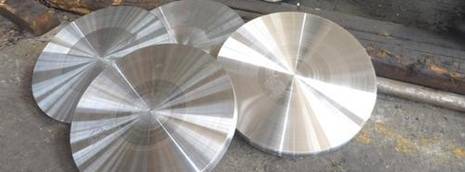

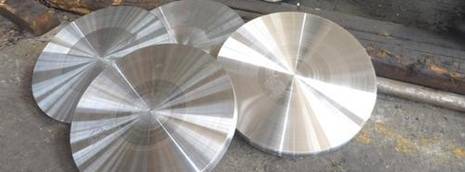

SMO 254 Circles / Rings Supplier & Exporter

Alloy 254 SMO Circles, ASTM A240 SMO 254 Rings, 254 smo material circles, alloy 254 smo distributor of

circles, ss 254 smo rings, SMO 254 Circles Supplier in India.

SMO 254 Rings, SMO UNS S31254 Circles, SMO DIN 2.4819 Rings, 254 SMO Circles Supplier

We engraved a position of prominent supplier, exporter and manufacturer of SMO 254 Circle and

offer a widespread range of the same to our clienteles. These SMO 254 Rings (UNS S31254) have

high resistance to stress corrosion cracking. Hardening is possible only through cold reduction. It should be

understood however that the material will be more difficult to work than other austenitic stainless steels due

its high work hardening rate. 254 SMO Circle is used in petroleum production, saltwater handling, and more. 254

SMO Rings have a good weldability and the methods used for welding conventional austenitic steels are used. It

also has high resistance to pitting, crevice and general corrosion. We also offer these products in diverse and

made-to-order specifications.

What are 254 SMO material circles?

254 SMO material is a 254 austenitic stainless steel, which boasts great corrosion resistance and mechanical

strength despite its low carbon content. 254 SMO material circles can be used in any number of applications. 254

SMO circles are versatile and cylindrical items. In general, 254 SMO rings are highly temperature resistant and

weldable, making them the perfect choice for various specialized projects. No matter the intended use, 254 SMO

material circles offer the best combination of quality and durability.

How To Weld 254 SMO Rings?

Welding 254 SMO rings can be difficult, but with the right equipment and proper technique, it can yield strong

and reliable welds. 254 SMO is a type of stainless steel alloy that requires specific welding processes to

ensure optimal strength and durability. Different methods, such as MIG or TIG welding, may be required when

welding 254 SMO rings; both options have advantages and disadvantages depending on the application. It's

important to use the right strategies when welding 254 SMO rings to create secure joints sure to last.

Additionally, protective gear must be worn because 254 SMO produces fumes that can cause skin irritation or

other health concerns. However, with appropriate safety precautions, 254 SMO rings can be welded safely and

effectively with incredible results!

Specifications:

Standards: EN, DIN, JIS, ASTM, BS, ASME, AISI

Rings Diameter: 3" OD up to 48" OD Up to 900 lbs max

Circle Diameter: 3" DIA up to 38" DIA 1500 lbs max

Specifications : ASTM A240 / ASME SA240

Forms : Forging & Plate Cut

SMO 254 Circles / Rings Equivalent Grades

| STANDARD |

UNS |

WERKSTOFF NR. |

EN |

AFNOR |

SIS |

| SMO 254 |

S31254 |

1.4547 |

X1CrNiMoCuN20-18-7 |

Z1 CNDU 20.18.06Az |

2378 |

smo 254 chemical composition of rings

| Element |

Content (%) |

| Iron, Fe |

55.69 |

| Chromium, Cr |

20 |

| Nickel, Ni |

18 |

| Molybdenum, Mo |

6.1 |

| Nitrogen, N |

0.20 |

| Carbon, C |

0.010 |

Other grades of SMO 254 Circles / Rings

| SMO 254 Circles |

| ASTM A240 Alloy 254 SMO Rings |

| SMO 254 Rings |

| SMO UNS S31254 Circles |

| 254 SMO Rings |

| SMO DIN 1.4547 Rings |

| Alloy 254 SMO Circles Suppliers |

| Alloy 254 SMO Rings Exporter |